IT's been a while since, i began using platinum material to fortify the sterling/argentium nibs.

it's been quite a journey, but still not finished yet.

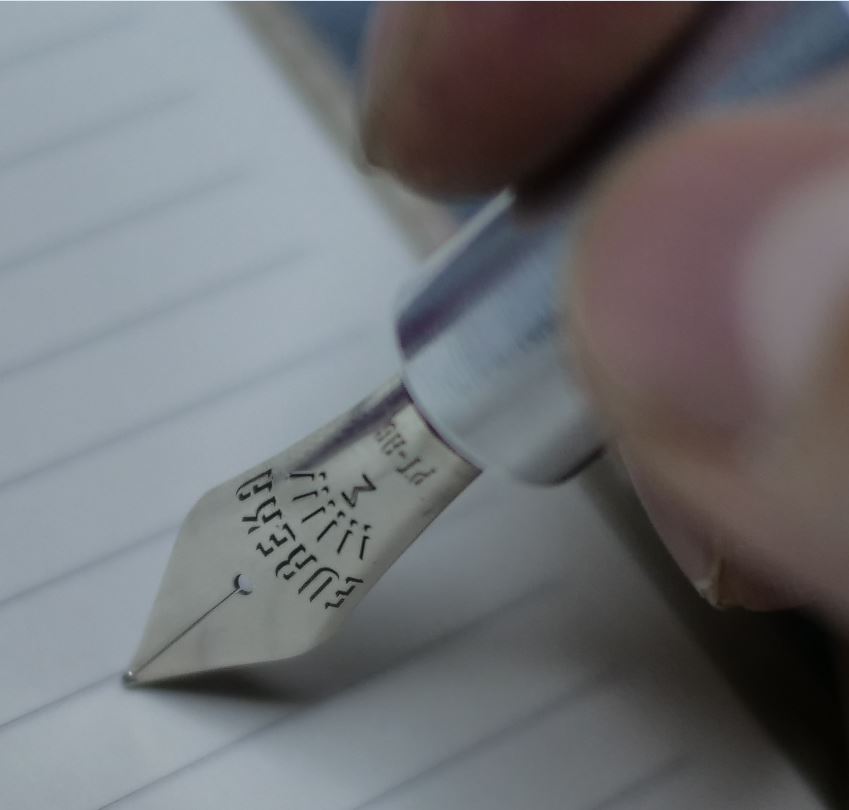

today, i created my first platinum silver nib, an improvement from argentium silver nib.

it has superior scratch resistance and tarnish resistance

in terms of tarnish resistance, argentium silver did better job than sterling, but still not satisfy my standards.

in conjunction with silver cleaning liquid, tarnish can be removed quite easily, but to some, it can be a chore.

therefore platinum-silver nib research was started, followed by, higher yield gold-silver nib.

these nibs are favored by silver nib lovers.

and to satisfy their needs, the physical characteristics are similar to 14K gold nib.

expected tarnish resistance will be similar to stainless steel (argentium silver is worse than stainless steel), or better,

thanks to the addition of precious metals such as platinum and gold.

i've also further improved the newly made nib, by introducing an additional grinding step that improves the sealing of following components:

Grip, Nib, Feed.

although previous design did fairly well, I've improved it by factor of at least 2, probably achieves very good seal.

also further precision and stability of slitting procedure has also been achieved.

from the 10 nibs i cut, all of them had less than 0.03mm deviation from initially set target.

also, welding procedure has been changed to single to double step welding, to achieve better production stability.

all this research is very burdensome for just one person, but i've kept this way since the beginning.

from my experience good results seldom came, and it was physically tiring.

however, through continued persistence, things did improve by minuscule steps...

completed PT-AG nib from research.

still solving initial manufacturing difficulties, may not even be solvable... but still trying.

for higher yield production, AU-AG nib is better candidate and many of them are currently being made.

Testing previous generation material: Argentium silver.

this specimen has been left in open air for 3~5months.

surface tarnishing has been repeatedly observed, no matter what.

still less tarnishing than sterling silver, which would have become almost blackish by this point.

tarnish layer is only micron level thickness and doesn't affect nib's physical performance.

and can be easily removed with silver cleaning liquid, which will be done in the last photo

ten seconds of stirring in the silver cleaning liquid.

probably more time is needed, but it shows how easy it is to remove the nano~micron thickness tarnish layer.