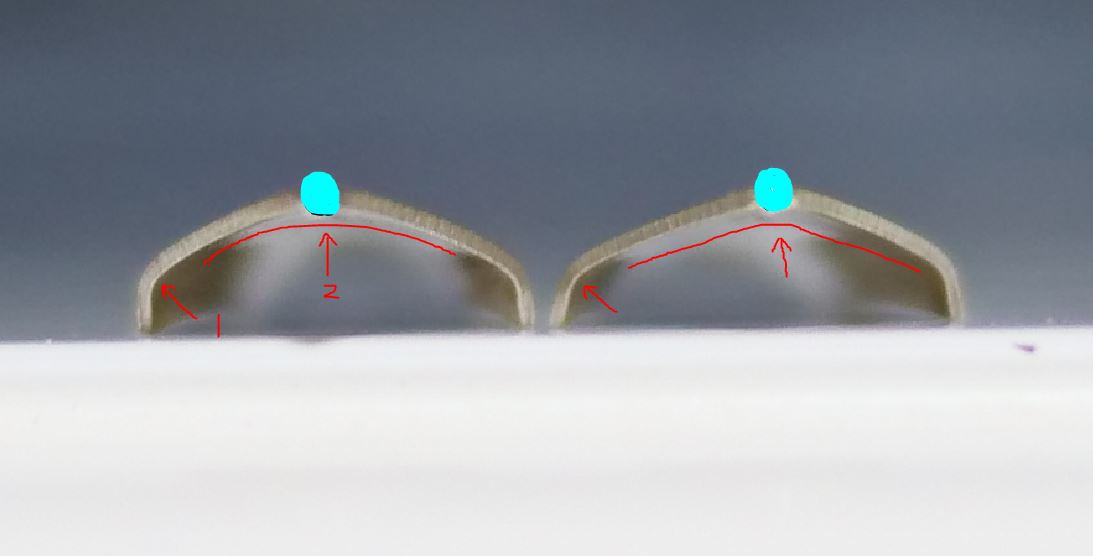

#1 --> not enough bending amount, thought to be an effect of "spring-back" phenomenon.

#2 --> V-bending phenomenon @ skyblue dot, thought to be inevitable.

so far, #1, 2 was wrongly thought to be a consequential result of bending a springy sheet material.

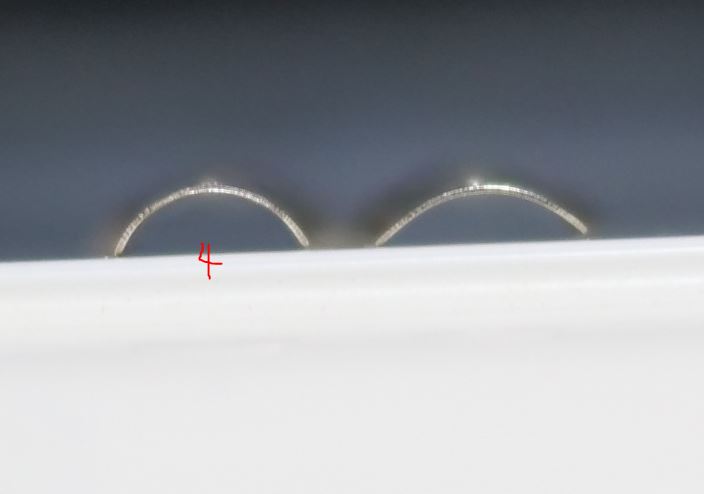

increasing press pressure by 10x improved overall shape.

especially, improving #1 was vital, because when the nib is slitted, a deformation occurs that cause "V type" slitting.

distance of #3 & #4 decreased

#4 is especially important, because the nib has to match the feed.

additional bending procedure was needed to match the feed, in the past.

improvement conclusion:

1) reduced V type slit

2) overall shape closely matching original design

3) improved shape @ #4, increasing production efficiency

4) overall slit width reduced to < 0.1mm, from heart hole to point

5) increased compression of the nib, increases overall springiness

6) increased compression of the nib, increases overall surface hardness