I've always wanted to do Raden (techinique using mother of pearl) for urushi pens.

however, due to its dubious durability i stopped myself from doing so.

But I really do love the look of mother of pearl.

above all it's a true beauty formed 100% naturally.

therefore, i did not totally give up researching for super-durability raden technique.

and today i announce the new beggining of its development initiation.

typically 0.15~0.3mm thickness mother of pearl is used for raden.

since body of the fountain pen is curved, it must be broken into small pieces.

if not it is highly likely to crack or fall off all together

so, the following reason is why traditional raden method is unstable for non-mosaic type raden on curved surfaces:

1) the curved feature of barrel / cap is the reason why the mother of pearl must be done in mosaic style.

2) even if one succeeds to attach whole mother of peral on to curved surface, the internal stress of mother of pearl will be detrimental to its durability

3) since the mother of pearl is so thin, urushi that gets filled in between the pieces are thin as well.

therefore in between urushi durability cannot be guaranteed for long term use

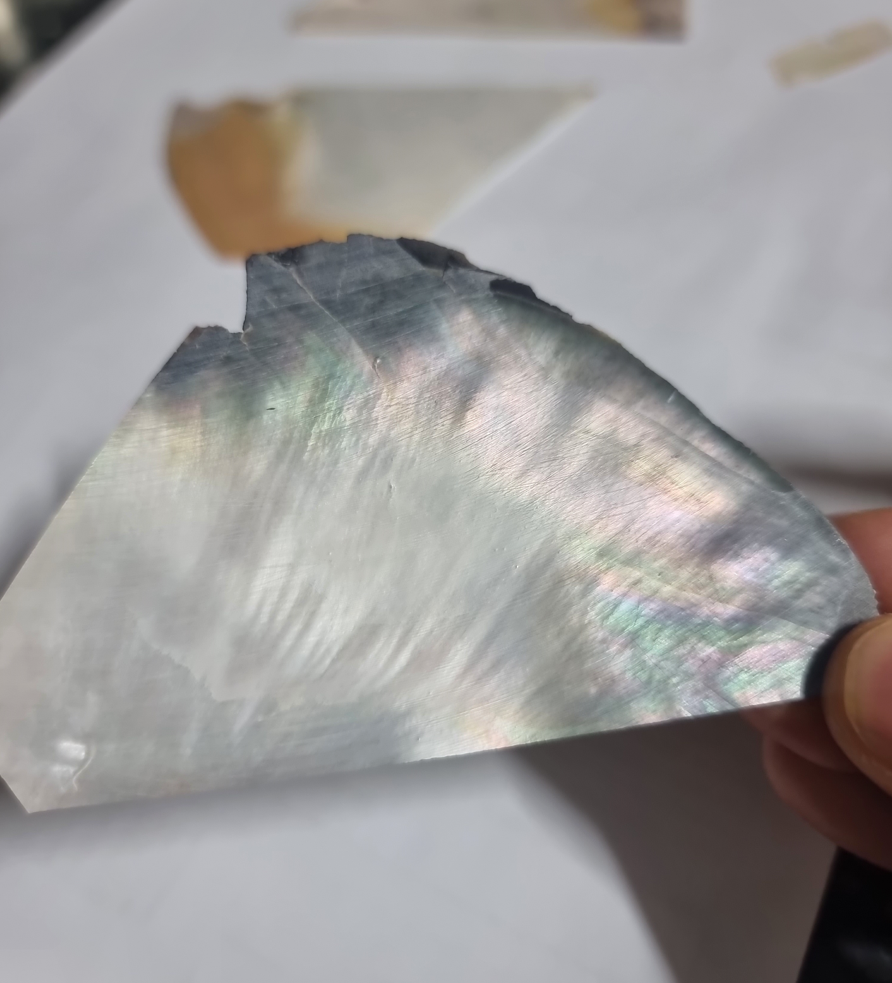

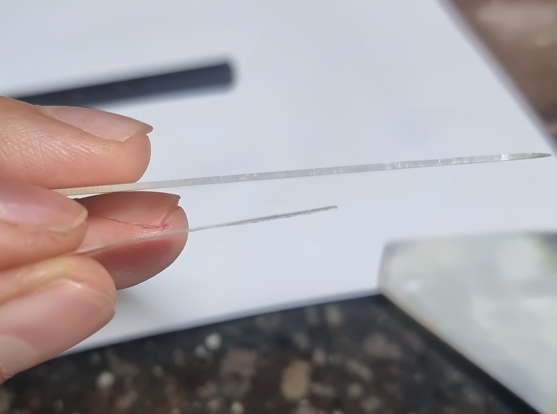

typical mother of pearl used for raden is 0.15~0.3mm as below

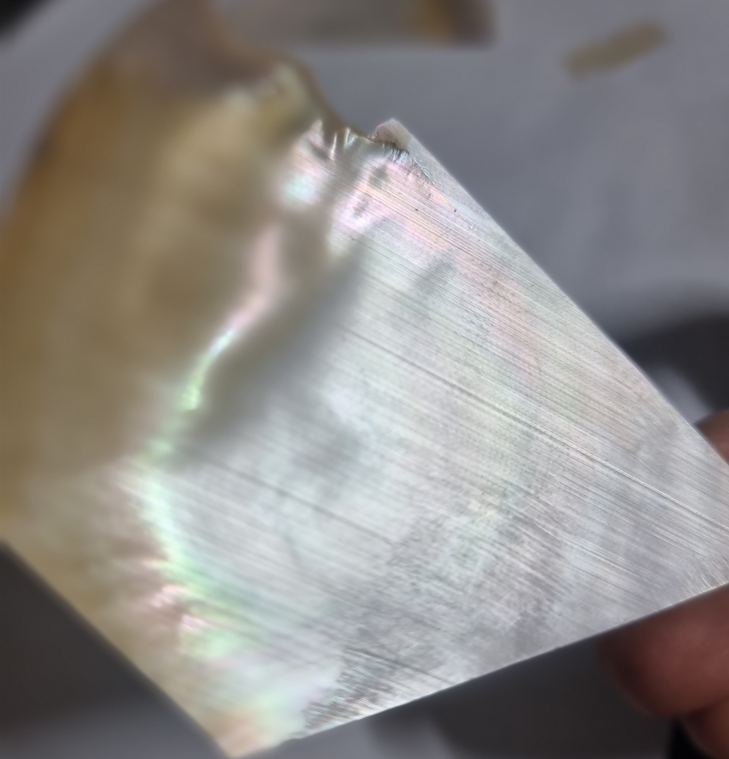

below is the comparison of what i will use for this research:

Left: 0.2mm thickness (typically used for raden: 0.15~0.3mm)

Right: 2.5mm thickness (used for this research)

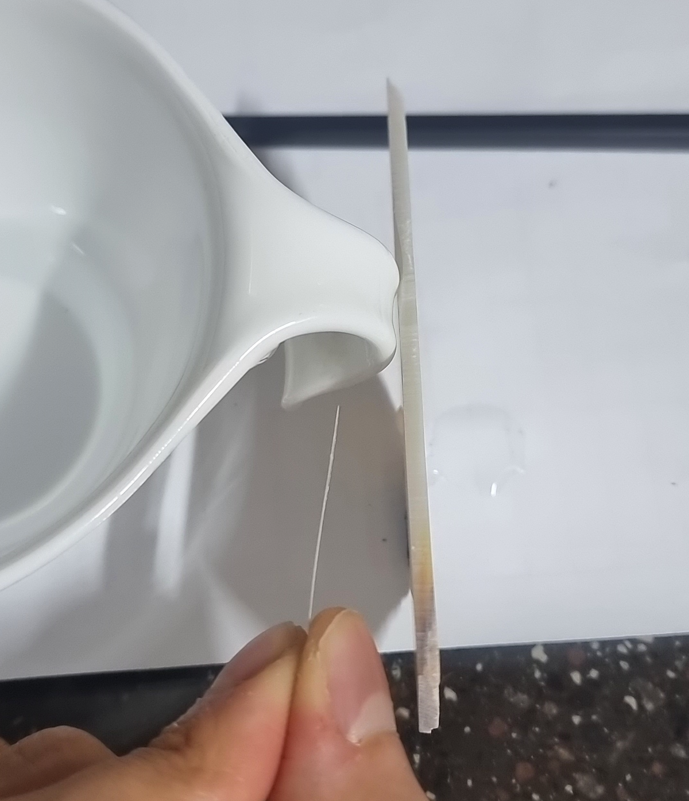

My objective is successfully attach to curved surface of barrel / cap using thick natural mother of pearl (even without breaking them into small pieces)

the whole thick mother of pearl will be attached to curved surface without any compromise in durability.

rather it will be much more durable

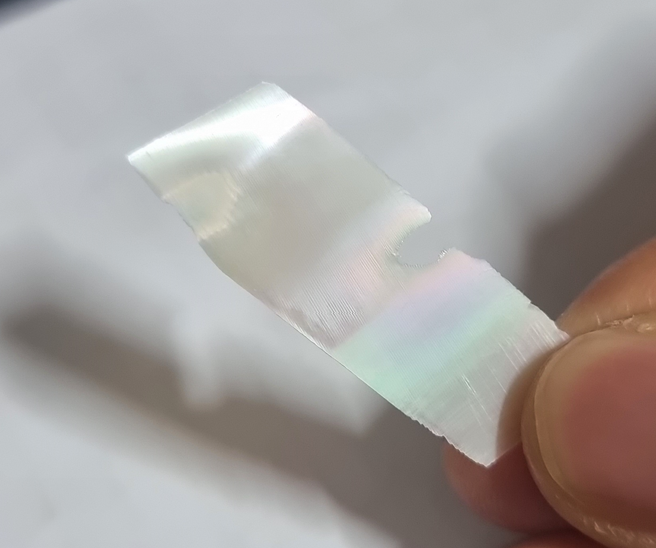

top: 1mm (used for this research)

below: 0.2mm (typically used for raden: 0.15~0.3mm)

these will be used for super-durability raden research