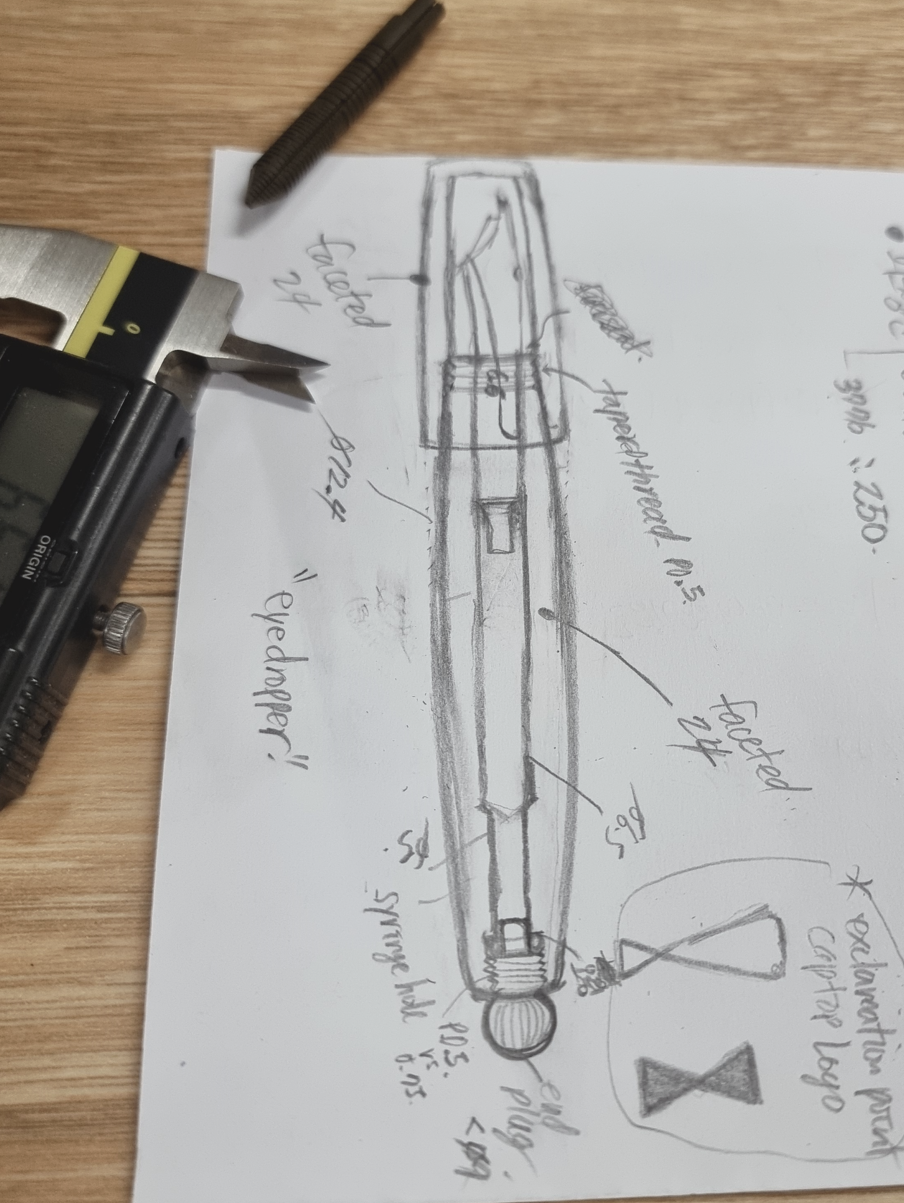

asymmetry micro's barrel & cap maximum thickness will be 12.4mm

so, it is a slim design.

when it comes to a slim fountain pen,

component durability is very important.

this is because when maximum thickness is thinner than usual,

all the component's wall thickness will be thinner as well.

◆ to maximize durability i decided to choose several key design points:

1. converter-less, eye-dropper type ink filling

using converter inevitably reduces wall thickess

2. thread size P0.5 instead of P0.75

reduced thread size will help increase component wall thickness

3. grip-less unibody barrel design.

eliminating the mating features of grip,

and eliminating grip itself will greatly help increase component wall thickness

◆ The Eureka Asymmetry Micro will be made with

13mm rods of various materials:

- peek (green, blue)

- ultem

- ebonite

◆ Barrel:

- unibody, grip-less solid design

- external feature: 24 facets precision machined

- cap threading feature located at the front of the barrel (tapered thread)

◆ Cap:

- external feature: 24 facets precision machined

- length shorter than usual

◆ Feed:

- compatible with eureka 5th gen. ebonite feed

◆ ink filling method:

- eye-dropper type with end plug

- the end plug can be installed & removed by thread on/off

- there's a o-ring installed on the end plug, that provides seal.

- when syringe-filling the ink, ink leak from the nib is inevitable,

so the nib must be located above opened ink bottle to recollect the dripping ink.

the leak dripping amount shouldn't be a lot, less than 10 drops / fill.

- excess ink below the nib (collected in the frontal part of the feed), can be eliminated by,

wiping, lightly rubbing on the edge of opened ink bottle, or just start writing (although the flow will be much greater usual for a while)

◆ compatible nibs:

12 different kinds of nibs from various brands will be compatible (needs matching ebonite feed)

so far, this is just a concept that only exists on paper.so much more work and prototyping will be required for actual production.

thank you.